Imagine a world where machine breakdowns are a rarity, not an expectation. Where critical equipment “tells” you it needs attention before it fails, saving millions in downtime and repair costs.

This isn’t science fiction; it’s the promise of predictive maintenance (PdM), and vibration analysis is at its heart and we in SmarVibe have for solutions for your business!

In today’s industrial landscape, unscheduled downtime is a nightmare. From manufacturing plants to energy grids, a sudden equipment failure can cripple operations, leading to significant financial losses and even safety hazards. This is where PdM steps in, using data to anticipate issues and enable proactive interventions.

The Power of Vibration Analysis in Predictive Maintenance

Think of a machine as having a unique “heartbeat” – its vibration signature. When this heartbeat changes, it’s often an early warning sign of trouble. Vibration analysis involves collecting and interpreting this vibrational data to detect abnormalities, identify the root cause of issues (like bearing wear, misalignment, or imbalance), and predict when a component might fail.

Traditionally, this has been a specialized field, often relying on expert human interpretation of complex vibration patterns. However, with the explosion of data and advancements in data science and artificial intelligence (AI), we’re entering a new era of even more powerful and precise predictive maintenance.

The Rise of Explainable AI (XAI) for Trustworthy Predictions

While AI models can be incredibly accurate at predicting failures, they often operate like “black boxes.” They give you an answer, but not the why. For critical applications like industrial machinery, knowing why a machine is predicted to fail is paramount for engineers and technicians to trust the system and take effective action. This is where Explainable Artificial Intelligence (XAI) becomes indispensable.

XAI aims to make AI models transparent and understandable. It’s about bridging the communication gap between complex algorithms and human experts. In predictive maintenance, XAI allows us to:

- Understand the reasoning: Why is the AI predicting a bearing failure? What specific vibration patterns or features led to that conclusion?

- Validate the model: Is the AI learning what we expect it to, or is it picking up on spurious correlations?

- Build trust: When maintenance teams understand the AI’s logic, they’re more likely to rely on its predictions and integrate it into their workflows.

- Improve decision-making: Clear explanations enable better-informed decisions about maintenance scheduling, resource allocation, and troubleshooting.

How XAI, Especially Fuzzy Rules, Can Transform Vibration Analysis

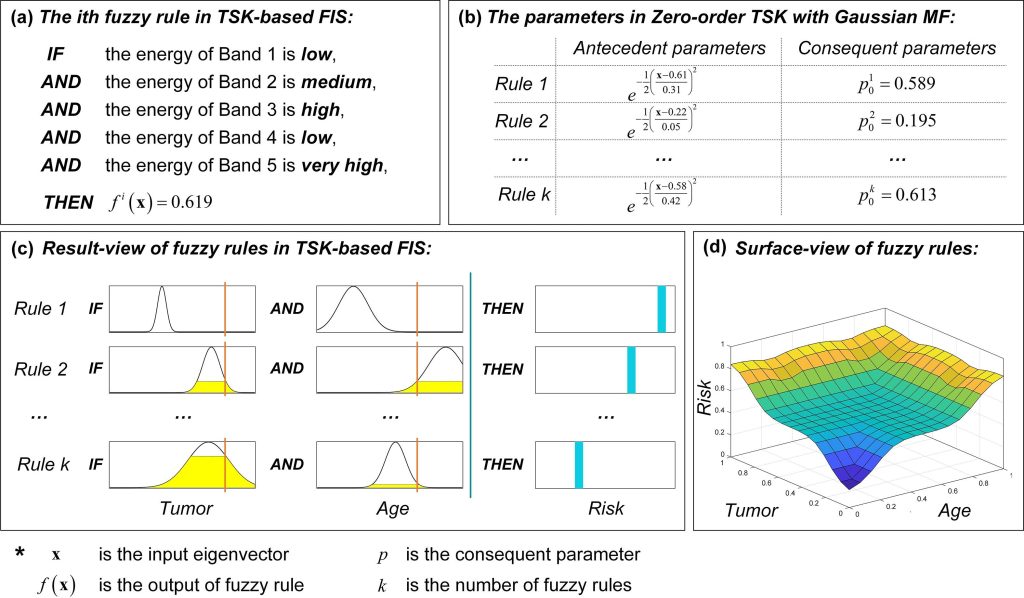

One particularly promising XAI technique, highlighted in recent research, involves the use of fuzzy rules embedded within a Fuzzy Inference System (FIS). This approach offers a unique blend of human-like reasoning and AI power.

Here’s how it works and why it’s so impactful for vibration analysis:

- Human-like Reasoning with “IF-THEN” Statements: Fuzzy rules operate on “IF-THEN” logic that mimics how humans reason. For example: “IF (vibration amplitude is high) AND (frequency is around 2x motor RPM), THEN (likelihood of unbalance is very high).” This makes the AI’s decision process intuitive and easy to grasp for maintenance engineers who are already familiar with these concepts.

- Handling Imprecision and Uncertainty: Unlike traditional crisp logic (yes/no, 0/1), fuzzy logic deals with degrees of truth. A vibration might be “somewhat high” rather than just “high” or “not high.” This ability to handle linguistic terms and subtle variations in data is crucial for the often-noisy and complex world of industrial vibration.

- Bridging the Gap Between Data and Expertise: Fuzzy rules can be derived from expert knowledge (e.g., a seasoned vibration analyst’s insights) or learned directly from data. This allows for a powerful synergy between human expertise and machine learning, creating models that are both accurate and interpretable.

- Clearer Explanations: FIS models can present their reasoning in various ways:

- IF-THEN statements: The most natural and understandable form for human users.

- Parameter lists: Providing insights into the underlying numerical values that define the linguistic terms.

- Visualizations: Surface plots or result views that visually demonstrate the relationship between input vibrations and predicted outcomes.

Consider a scenario in predictive maintenance for a large industrial motor. We’re collecting vibration data – amplitude, frequency, phase. An XAI system using fuzzy rules could analyze this data and generate an explanation like:

“IF the overall vibration amplitude is medium-high AND the vibration at the bearing’s natural frequency is high, THEN the risk of bearing failure is elevated.”

This kind of clear, actionable insight empowers maintenance teams to investigate the specific bearing, understand the likely issue, and schedule proactive maintenance before a catastrophic failure occurs.

Beyond Fuzzy Rules: A Spectrum of XAI Techniques

While fuzzy rules offer exceptional interpretability, other XAI techniques also play a crucial role in making sense of predictive maintenance models:

- SHAP (SHapley Additive exPlanations): This game-theoretic approach quantifies the contribution of each feature to a model’s prediction. For vibration analysis, SHAP can tell us precisely how much a change in a specific frequency band contributed to the prediction of a fault.

- LIME (Local Interpretable Model-agnostic Explanations): LIME explains individual predictions by creating a simple, interpretable model around that specific data point. If a machine is predicted to fail, LIME can highlight which input features (e.g., specific vibration components) were most influential for that particular prediction.

- Heat Maps: These visualizations can be used to highlight “hot spots” in complex vibration signals or frequency spectra, indicating areas of high relevance to a predicted fault.

The Path Forward

The integration of XAI, particularly fuzzy rule-based systems, into predictive maintenance for vibration analysis is a game-changer. It moves us beyond mere predictions to understandable predictions, fostering trust and enabling more effective, proactive maintenance strategies.

As we continue to generate vast amounts of data from industrial assets, the demand for transparent and interpretable AI models will only grow. By embracing XAI, we can unlock the full potential of data science to ensure the longevity, efficiency, and safety of our critical machinery, paving the way for a more reliable and predictable industrial future.

Let’s connect with us and design your own dedicated Explainable AI solution!