Introduction

In the era of the Industrial Internet of Things (IIoT), businesses are harnessing the power of Machine Learning (ML) to enhance operational efficiency, predictive maintenance, and data-driven decision-making. Among the myriad of tools available for ML, PyTorch and PyTorch Lightning have emerged as game-changers. This article delves into the pivotal role of PyTorch and PyTorch Lightning in advanced IIoT, particularly in vibration analysis. We will explore the business contexts, explain their significance in ML, and highlight essential supportive libraries. Furthermore, we will share success stories demonstrating the transformative potential of these libraries in data processing.

1. The Business Context: Why PyTorch and PyTorch Lightning?

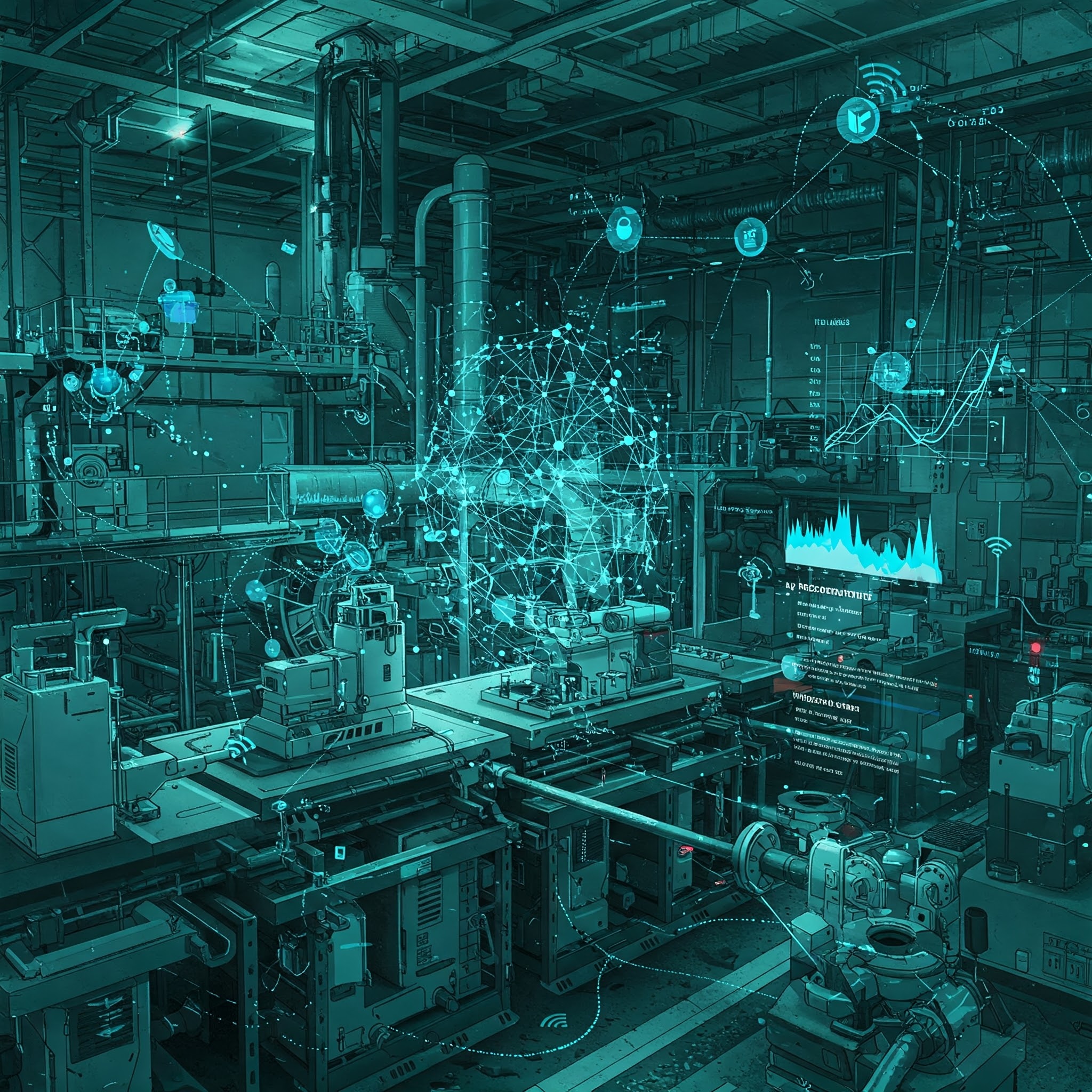

1.1 The IIoT Ecosystem

The IIoT ecosystem integrates physical machines with digital systems, enabling real-time data collection, monitoring, and analysis. Industries such as manufacturing, energy, and transportation leverage IIoT to optimize operations, minimize downtime, and enhance safety.

1.2 The Significance of Vibration Analysis

Vibration analysis is a cornerstone of predictive maintenance in IIoT. By monitoring machine vibrations, engineers can detect abnormalities, diagnose issues, and prevent equipment failures. Effective vibration analysis requires advanced ML models capable of processing vast amounts of data in real-time.

1.3 The Power of Data Logging

Data logging involves the continuous collection and storage of data over time. In IIoT, data logging is critical for tracking machine performance, identifying trends, and making informed decisions. Robust data logging solutions must efficiently handle diverse data types and large datasets.

2. Why PyTorch and PyTorch Lightning?

2.1 Flexibility and Ease of Use

PyTorch is renowned for its flexibility and ease of use. Its dynamic computational graph allows developers to modify the network during runtime, facilitating experimentation and debugging. PyTorch Lightning extends PyTorch by providing a high-level interface that simplifies the training process and ensures reproducibility.

2.2 Performance and Scalability

PyTorch offers exceptional performance, particularly in GPU-accelerated computations, making it suitable for handling large-scale IIoT data. PyTorch Lightning enhances scalability by abstracting boilerplate code and providing tools for distributed training, enabling efficient model deployment across multiple devices.

2.3 Strong Community and Ecosystem

PyTorch and PyTorch Lightning benefit from a robust and active community. The extensive ecosystem includes a plethora of libraries and tools tailored for ML tasks, making it easier for engineers to develop, test, and deploy models.

3. Essential Libraries for Training and Inference in IIoT

3.1 NumPy

NumPy is the foundational library for numerical computing in Python. It provides support for large, multi-dimensional arrays and matrices, along with a wide range of mathematical functions.

3.2 SciPy

SciPy builds on NumPy and offers additional functionalities for scientific computing. Its modules for optimization, integration, and signal processing are invaluable for vibration analysis.

3.3 Pandas

Pandas is a powerful library for data manipulation and analysis. Its DataFrame structure is essential for handling structured data in IIoT applications.

3.4 Matplotlib and Seaborn

Matplotlib and Seaborn are visualization libraries that enable the creation of static, animated, and interactive plots. They are crucial for visualizing data trends and patterns in IIoT.

3.5 OpenCV

OpenCV is a comprehensive library for computer vision tasks. It provides tools for image and video processing, essential for visualizing and interpreting sensor data in IIoT.

3.6 Scikit-Learn

Scikit-Learn is a versatile library for classical ML algorithms. It provides tools for data preprocessing, model selection, and evaluation, complementing the deep learning capabilities of PyTorch.

3.7 TensorBoard

TensorBoard is a visualization toolkit for monitoring ML experiments. It integrates seamlessly with PyTorch and PyTorch Lightning, enabling real-time tracking of metrics, visualizations, and performance.

4. Success Stories: PyTorch in Action

4.1 Predictive Maintenance in Manufacturing

A leading electronics manufacturer implemented an IIoT solution using PyTorch and PyTorch Lightning to monitor vibrations in assembly line machinery. By leveraging NumPy, SciPy, and PyTorch, they developed deep learning models that identified potential equipment failures before they occurred. This proactive approach significantly reduced downtime, increased productivity, and saved costs.

4.2 Energy Sector: Wind Turbine Monitoring

In the renewable energy sector, a company specializing in wind turbine maintenance utilized PyTorch for vibration analysis and data logging. With the help of Pandas, OpenCV, and PyTorch, they created a real-time monitoring system that tracked turbine performance. The system provided actionable insights, enabling timely interventions and optimizing energy production.

4.3 Transportation: Railway Infrastructure

A railway operator deployed a PyTorch-based IIoT solution to monitor the condition of tracks and rolling stock. Using PyTorch Lightning for distributed training, NumPy for numerical computing, and SciPy for signal processing, they developed a robust system that detected anomalies and predicted maintenance needs. This initiative improved safety, reduced operational disruptions, and extended the lifespan of critical infrastructure.

5. Conclusion

PyTorch and PyTorch Lightning have emerged as indispensable tools in the realm of advanced IIoT, offering unparalleled flexibility, performance, and scalability. Their application in vibration analysis and data logging has transformed industries, enabling predictive maintenance, optimizing performance, and reducing costs. As IIoT continues to evolve, PyTorch’s role will only become more significant, driving innovation and shaping the future of industrial operations.

By embracing PyTorch and PyTorch Lightning, ML engineers and IoT engineers can leverage their capabilities to develop cutting-edge solutions that propel industries towards a smarter, more efficient, and interconnected future.

Feel free to adapt and expand on these sections to fit your needs. If you have specific points you’d like me to elaborate on, just let me know!