Introduction

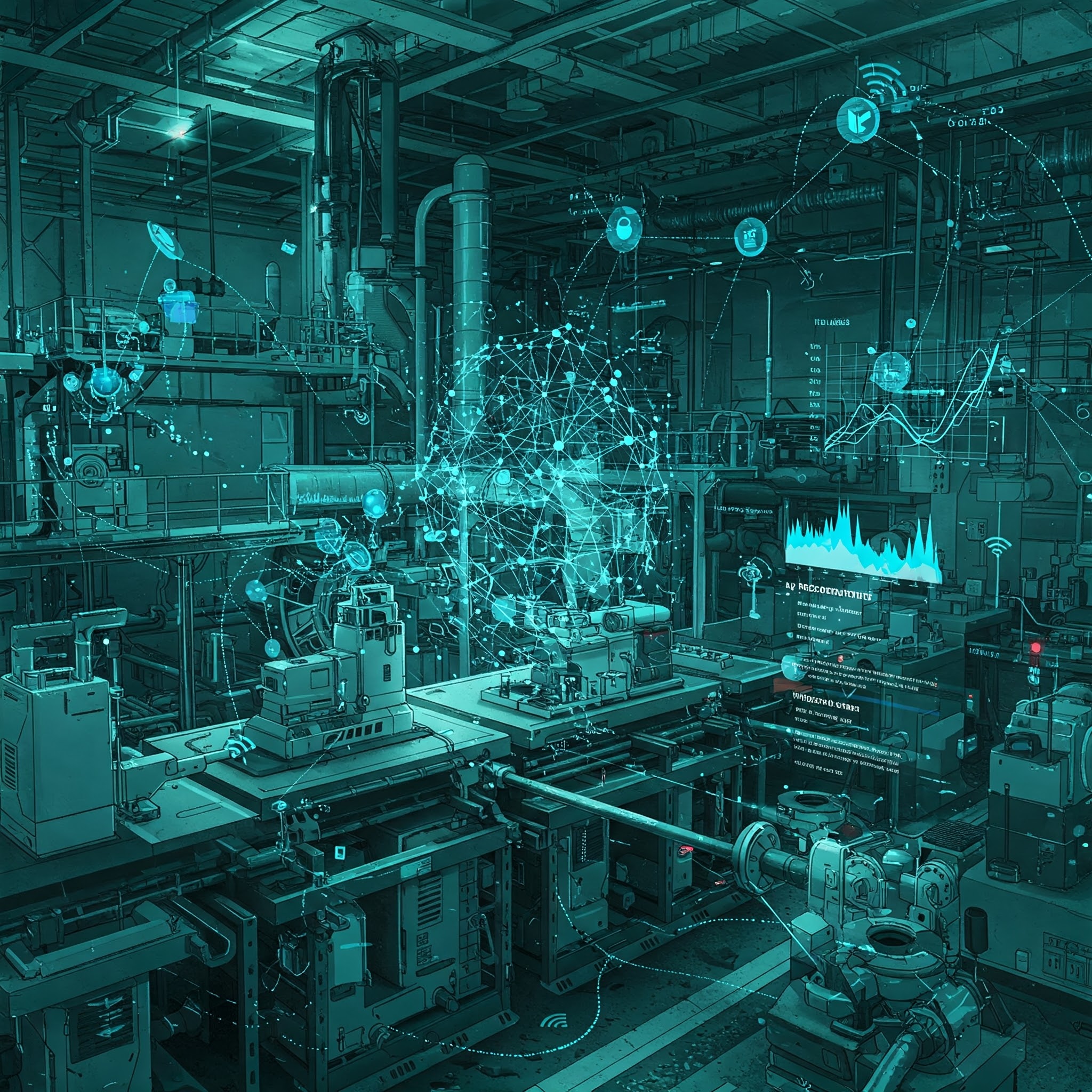

The rise of Industry 4.0 has transformed traditional manufacturing into a fully digital ecosystem, where data-driven decisions enhance efficiency, reduce downtime, and optimize production processes. As factories become more connected, businesses are shifting from cloud-centric architectures to edge computing solutions—bringing intelligence closer to the machines and enabling real-time operations.

By decentralizing processing power, smart factories can leverage AI, automation, and IoT-driven analytics at the edge, reducing latency, enhancing security, and ensuring instant decision-making on the factory floor. This article explores how edge computing is revolutionizing modern manufacturing, key technologies enabling the transition, and real-world benefits for industries embracing this next-generation infrastructure.

The Evolution from Cloud to Edge

The Role of Cloud Computing in Manufacturing

For years, cloud computing has powered digital transformation in industrial settings by providing centralized data storage, computing resources, and analytics platforms. Cloud-based solutions allow manufacturers to monitor factory operations remotely, optimize workflows, and integrate AI-driven predictive maintenance models.

However, cloud computing has its limitations when applied to time-sensitive industrial processes:

- Latency Issues – Remote cloud servers introduce delays that impact real-time decision-making.

- Network Dependency – Factories rely on stable internet connectivity, which is not always guaranteed.

- Data Privacy Concerns – Sensitive production data is stored externally, increasing cybersecurity risks.

- High Bandwidth Costs – Constantly transmitting raw sensor data to the cloud leads to excessive network traffic and expenses.

Edge Computing: A Paradigm Shift in Smart Factories

Edge computing addresses cloud limitations by bringing computation closer to production environments. Instead of relying on remote servers, edge devices, industrial gateways, and embedded controllers process data locally at manufacturing facilities, ensuring ultra-fast response times and autonomous operations.

Key Advantages of Edge Computing in Smart Factories

✅ Real-Time Processing – Data is analyzed instantly, enabling predictive maintenance and adaptive manufacturing.

✅ Improved Security – Edge computing reduces data exposure by keeping sensitive information within factory premises.

✅ Lower Bandwidth Consumption – Only relevant data is sent to the cloud, reducing network costs.

✅ Offline Functionality – Factories continue operating efficiently even in remote locations with limited internet access.

Key Technologies Powering Edge Computing in Smart Factories

1. Industrial IoT & Sensor Networks

Modern factories are equipped with IoT-enabled sensors that collect real-time data on machine performance, temperature, vibration, and other critical parameters. Edge computing processes sensor data locally, ensuring fast responses to equipment failures and operational adjustments.

2. Edge AI & Machine Learning

Artificial intelligence at the edge enables predictive analytics, anomaly detection, and automated decision-making. Technologies such as TensorFlow Lite, Edge Impulse, and AI-enabled microcontrollers allow factories to analyze complex data without cloud dependency.

3. Industrial IoT Gateways & Protocols

Smart factories require seamless interoperability between various machines, sensors, and enterprise systems. Edge-powered IIoT gateways facilitate protocol conversions and secure data exchange using OPC UA, MQTT, and ROS 2, ensuring efficient communication across industrial networks.

4. Real-Time Operating Systems (RTOS) for Embedded Computing

Factories rely on real-time operating systems such as FreeRTOS, Zephyr, and Linux-based Yocto to manage embedded controllers that perform low-latency, deterministic operations critical for automation.

5. 5G & Private Industrial Networks

Ultra-fast connectivity solutions like 5G and private industrial wireless networks enhance edge computing capabilities, enabling near-instant communication for autonomous robotics, remote monitoring, and predictive maintenance.

How Smart Factories Leverage Edge Computing

1. Predictive Maintenance & Machine Health Monitoring

Factories use edge AI-powered analytics to detect early warning signs of equipment failures before they occur. This minimizes downtime, reduces repair costs, and enhances productivity by optimizing maintenance schedules based on real-time machine health data.

2. Autonomous Robotics & Industrial Automation

Edge computing enables real-time control of autonomous machines, ensuring efficient material handling, precision manufacturing, and robotic assembly operations without cloud latency.

3. Energy Optimization & Sustainability

Smart factories optimize energy consumption by processing environmental data at the edge, dynamically adjusting HVAC systems, lighting, and power distribution to reduce waste and lower operational costs.

4. Intelligent Quality Control & Computer Vision

Factories integrate edge-powered image processing to detect product defects instantly. AI-driven computer vision systems perform high-speed inspections, ensuring consistent product quality without network delays.

5. Secure Factory Networks & Cybersecurity

By processing sensitive industrial data locally, edge computing reduces security vulnerabilities, ensures data encryption, and enhances cyber resilience against external threats.

Case Study: Edge Computing in Action

Automotive Manufacturing & Edge AI

An automotive company implemented edge AI-enabled machine vision for real-time quality inspections on production lines. By processing images locally at edge servers, defects were detected instantly, reducing waste and improving overall assembly efficiency.

Energy Sector & Smart Grid Optimization

A power plant deployed edge computing for predictive maintenance of critical turbines. By analyzing vibration and temperature data locally, equipment failures were prevented, avoiding costly disruptions in energy supply.

Smart Logistics & Warehouse Automation

A logistics provider integrated edge-powered autonomous robots to optimize inventory management. With real-time path planning and decision-making at the edge, operational efficiency significantly improved while reducing dependency on cloud-based controls.

Challenges & Future Trends in Edge Computing for Smart Factories

Challenges

- Integration Complexity – Retrofitting legacy machines with edge computing solutions requires specialized expertise.

- Security Risks – Edge networks need advanced encryption and authentication mechanisms to prevent cyberattacks.

- Infrastructure Costs – Deploying edge servers and IoT gateways requires upfront investment, though long-term savings outweigh costs.

Future Trends

🚀 AI-Optimized Edge Devices – Industrial AI models will become more efficient for autonomous edge processing. 🚀 5G-Enabled Smart Factories – Faster connectivity will unlock seamless automation and real-time analytics. 🚀 Hybrid Cloud-Edge Architectures – Factories will adopt decentralized computing with both local and cloud resources.

Conclusion

The transition from cloud-centric infrastructure to edge computing is redefining the future of smart factories—unlocking real-time intelligence, autonomous operations, and secure, decentralized processing.

By embracing edge computing, manufacturers gain faster insights, greater efficiency, and enhanced cybersecurity, ensuring seamless industrial automation in an increasingly connected world.

Are you ready to revolutionize your smart factory with edge computing? Let’s build the future together! 🚀